Front or Outboard Side Bends

Wheels are shaped like a bell. The outboard side of the wheel is the spoke side and is significantly stronger than the inboard side, where there are no spokes. Since wheels are all constructed this way, outboard side bends are the most difficult to repair. There is also a possibility of refinishing needed for this type of front bents due to the higher heat and possible tool marks left on the face of the rim. But with our patented straightening processes, we try our best to minimize cosmetic or tool mark damage to avoid further costs due to refinishing.

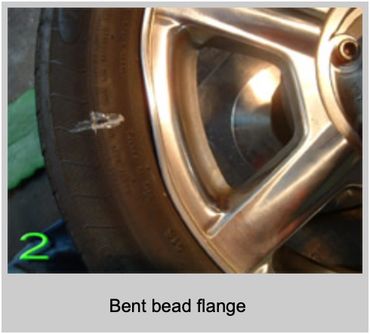

Any damage to a spoke on a wheel cannot be straightened. The photo on the left (#1)shows a chrome wheel with a spoke bent so badly that it is actually cracked under the chrome. On the right (#2), the bead flange of the wheel is bent significantly but should be repairable unless there is a significant hairline crack on the inside bead. This can only be determined upon close inspection of the wheel.

On the left a more severe bend can be seen in the bead flange on a machined wheel (#3). This is an example of a wheel that would most likely be replaced due to multiple bent spots, again we would recommend us to physically inspect rim to confirm. The bead damage (#4) to the machined wheel on the right would mostly likely be repaired. However, since the metal on the outboard side will not move as easily as on the inboard side, the necessary straightening process could leave some noticeable tool marks.

The bead and flange of the wheel on the left (#5) can be straightened, even though the bend extends down into the barrel slightly. Our dual axis straightening capability allows us to do this repair, leaving little or no evidence of tool marks. Another wheel (#6) with a more severe bend would most likely be unrepairable.

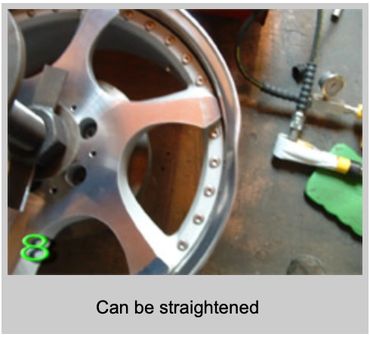

The bead flange of the wheel on the left (#7) is bent too severely to be straightened. Any abrupt front side bend that severe is most likely cracked, as is this wheel. A closer inspection of the photo will reveal another crack on the left side, just between the spokes. The flat bead of the sport wheel on the right (#8) can probably be straightened but the possibility of tool marks from the straightening process might be evident.

REAR OR INBOARD SIDE BENDS

The inboard side is more flexible and generally requires less heat than the outboard side of the wheel. Another reason that this type of straightening is more successful is because minor marks left by the straightening process will not affect the cosmetic appearance of the wheel.

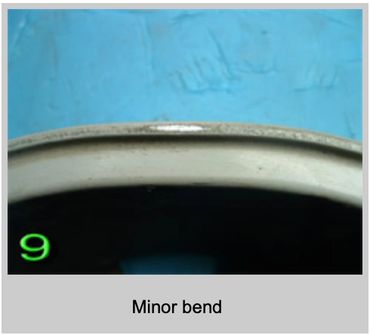

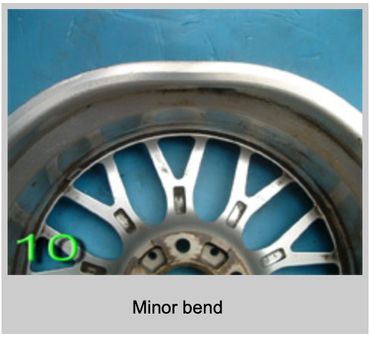

Both of these minor bends (#9 and 10) can easily be straightened. Although they look insignificant, they could eventually cause ancillary damage to other components such as tires and suspension systems.

These (#11 and #12) are more severe bends. As long as there are no cracks evident during preliminary inspection, straightening should be possible. Notice that although the raised beads are bent significantly, the bends extending down into the barrel are not as severe.

These bends (#13 and 14) are wider and the bends extend down farther into the barrel of the wheel. These repairs require multiple axis pressure applications and our experienced professionals are the only ones who have the patented equipment necessary to straighten wheels like these.

Although the bend in the wheel on the left (#15) is not as abrupt as some of the others pictured, it is just as difficult to straighten without the proper multiple axis pressure application equipment. That wheel as well as the one on the right (#16), shown with multiple bends, can be straightened. “Truing” the wheel to acceptable roundness tolerances and a balanceable condition, concludes all of our straightening processes.

Please note that there is always a possibility of cracking a bent rim even how insignificant the flat spot might be. These is due to different wheel construction and previous bends and repairs of the wheel.