Refinishing & Wheel Types

Wheel Designs And Repair Opportunities

Wheel Designs And Repair Opportunities

Wheel Designs And Repair Opportunities

Not all wheels can be repaired. Because of wheel design and construction and based on severity of damage, some wheels due to safety guidelines cannot be repaired. We would recommend replacing an unrepairable wheel with one of our refurbished factory OEM wheels at normally half the cost of a new one. If we don’t have one, we can try to locate one for you. Ask about our range of factory OEM wheels for sale. Inventory is constantly changing so call us for details.

There are four basic wheel finishes: painted, polished, machined (brushed aluminum), and chrome. Some others are a combination of all of these styles. Some wheels have raised beads while others have flat beads. All of these differences affect repair opportunities and strategies. WHAT WE NEED FROM YOU in order for us to determine if we can provide you with the most cost effective service, we need to know the following information from you:

- Year, Make and Model of the car - if it’s a factory OEM wheel

- Brand name -if it’s an aftermarket wheel

- The design or style of wheel you have - 5 spoke / 2 piece wheel, etc.

- Finish of the wheel – painted, polished, machined or chrome

- A description of the damage

Below are photos of different wheels with a brief description that might help you determine what style wheel you have and what method of construction was used to produce the wheel.

Describe Your Cosmetic Damage

Wheel Designs And Repair Opportunities

Wheel Designs And Repair Opportunities

Once you can describe the style of wheel you have all you need to do is, contact us with a description of the surface damage. Your description should include curb rash, scrapes, gouges, peeling, or other clearcoat failure. Once we are aware of all the requested information, we can better evaluate the repair cost and determine turn-around time.

Choose an example of your bent wheel

Wheel Designs And Repair Opportunities

Choose an example of your bent wheel

In addition to design and construction of the wheel, the location and severity of bends is also a determining factor in whether the wheel can be repaired. Describing bend damage is much more difficult than describing cosmetic damage. In order to make your description efforts as easy as possible, we have photographic samples of different bends and each photograph is numbered. See below to view the bends and compare the location and severity to your wheel.

Painted Wheels

The most common of all wheels are painted and they come in a wide variety of designs. Both photos show wide spoke designs but the important difference here is the design of the bead flanges. The wheel on the left has a flat bead design, which requires stick-on type balancing weights. The wheel on the right has a raised bead design, which is called the wheel weight flange for obvious reasons. Although pound-on type balancing weights can be used on this style wheel, the weights can actually damage the painted finish.

Here are two more styles of painted wheels with flat bead designs. Although some pained wheels resemble polished wheels, most painted wheels will reveal a metallic sparkle when viewed in bright sunlight. The wheel on the right is an artificial two-piece design. This replica design is common with aftermarket wheels but this construction is actually only one piece. The bolts that appear to be holding the wheel together are imitation. In some designs, the faux bolts are not even metal but are actually painted or chrome plated plastic.

Machined Wheels

You can always tell machined wheels by the thin lines cut into the aluminum surface, during the construction of the wheel. The lines, which resemble those of a CD, are sometimes so fine that they are nearly undetectable. The lines are what produce the rainbow effect that is customary with machined surfaces. Only the outermost surface of the wheel is machined and, on some machined wheels only a portion of the wheel is machined. The wheel on the left has a raised bead and is painted in the pockets. The outermost surface of the entire face has been machined, leaving the pockets as painted. Although the flat beaded wheel on the right resembles the aftermarket wheel shown in the photo directly above, it is actually a true two-piece wheel. The center is painted and the outer part is machined. The parts are constructed and finished separately and assembled after the finishing process is complete. All wheels with machined surfaces have clear-coated finishes.

Polished Wheels

The most difficult of all wheel styles to identify are polished. They are generally very expensive and are constructed of the highest quality material. Some polished finishes resemble painted finishes while others resemble chrome. Most chrome wheels finishes resemble those of a kitchen faucet, most of which are also chrome. Polished wheels have a lighter look and not all are clear-coated. Polished wheels that are not clear-coated have a much higher luster but they require a great deal of maintenance. You will never see a metallic sparkle on polished wheels when viewed in bright sunlight. The wheel on the left has a raised bead and on the right a flat beaded polished wheel is shown. Both are clear-coated and the wheel on the right is painted a dark gray in the pockets.

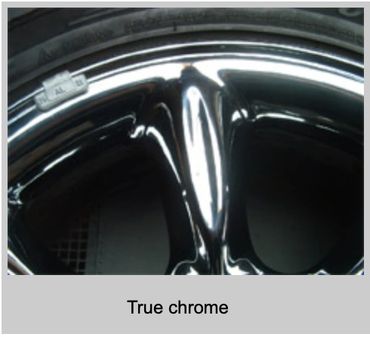

Chrome Wheels

The surface of chrome wheels is the most durable of all finishes. Although the chrome finish is thin, it is very strong and resistant to damage. However, in the colder climates, chrome has a tendency to peel from salted roads along with the freezing and thawing of water. Most chrome wheels finishes resemble those of a kitchen faucet, most of which are also chrome. Some chrome wheels are actually cladding construction. The wheel on the left is a true chrome wheel with a raised bead. On the right a chrome-clad wheel is shown. The face of the wheel is chrome but it is actually a vacuum formed piece of chrome-plated plastic, which is glued onto the aluminum wheel. The raised bead is not clad and the actual aluminum surface is exposed. Although most cladding is now plastic, some designs are made of steel.

*Once you know the style and construction of your wheel….

….call us and don’t forget to describe the damage!*